PCB Assembly: Surface Mount (SMT) vs. Through-Hole (PTH)

In recent days electronics have been growing more and more complex and integrating into people lives more every day, but despite major advances in performance each year there are still only two common ways that electrical components are soldered together to make circuits: Surface Mount Technology (SMT) and Plated Through-Hole (PTH). Both SMT and PTH describe ways that electrical components, such as capacitors, resistors, and microchips are soldered to a Printed Circuit Board, or PCB as they are commonly referred to. Both SMT and PTH soldering methods have their advantages and disadvantages. This article will try to outline some of the reasons one method may be preferable for a particular project.

Background: What are PCBs?

Printed circuit boards (PCBs) allow designers to created circuits with small copper wires, knows as traces, which are supported by a board. PCBs are produced by adhering one or more layers of copper to one or more layers of the substrate (which is typically FR-4 Fiberglass), and then etching away excess copper using acid. These traces can be connected from one layer to another layer of the PCB using drilled holes that are plated with copper, known as Vias. Most circuit boards you see on NightShade Electronics are 2-Layers, but PCBs can be produced with 1-20 or more layers of copper traces. PCBs with high layer counts are found in devices where many signals must travel through a small space, such as smartphones or computer motherboards.

Plated Through-Hole (PTH)

The most common type of components used for hand soldering is PTH components. PTH components have wires, or leads, coming out of the sides or bottom allowing you to solder them into a circuit, or stick into a breadboard. PTH components are called “through-hole” because the leads are normally inserted through a copper plated hole in a PCB and soldered to fix it in place. Generally speaking, PTH components are larger than SMT components, making them less ideal for the ever-shrinking world of consumer electronics.

Pros

- Hand assembly of PTH components into a PCB is relatively simple, making them ideal for anyone prototyping a small circuit.

- They can be used in a breadboard with no soldering required.

- They are generally stronger than SMT components. This makes them ideal for connectors and rugged circuitry.

Cons

- PTH components are more labor intensive to assemble. This makes them less ideal for production quantities.

- They are generally larger than SMT components, making them less ideal for small circuitry.

- Due to decreasing popularity, many new chips are not offered in a PTH package.

When should I use PTH components?

- Whenever physical strength is necessary, such as large connectors or large heavy components (transformers, inductors, large capacitors).

- If the project is a hand-made prototype or small production run.

- If prototyping with a breadboard is necessary.

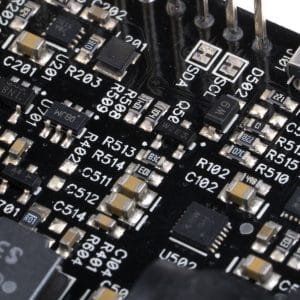

Surface Mount Technology (SMT)

SMT components are the most common type you will see used in modern electronics. They are smaller, cheaper, and easier to assemble in products quantities than their PTH counterparts. They are assembled at incredibly high speeds using Pick and Place machines, and the soldered using a Reflow Oven. This makes them ideal for mass production, but significantly more difficult for hand assembly. Soldering SMT components by hand take significantly more practice than PTH, and sometimes takes more equipment, such as a Reflow Oven or a Hot Air Rework Station.

Pros

- Generally smaller and cheaper than PTH components.

- Easier to assemble in high quantities with production equipment.

- More part options available due to increase in demand.

Cons

- Generally harder to hand assemble.

- Can be weaker for connections that need strength, such as connectors.

- Solder joints can crack and degrade due easier to their diminutive size.

When should I use SMT components?

- If your design must be small.

- If you need chips that don’t come in PTH packages.

- If you want to mass produce your design.